Garbage Truck Body Repair: What Northeast Waste Management Companies Need to Know

Downtime Hurts the Bottom Line

For waste management companies across Connecticut, Massachusetts, and Rhode Island, time truly is money. Each day a garbage truck is off the road can cost $448 – $760 in lost productivity per vehicle. For fleets operating under tight municipal contracts and strict route schedules, even a single truck out of service can create a domino effect of missed pickups, customer complaints, and costly overtime for other drivers.

And here in New England, where routes wind through narrow streets, tight cul-de-sacs, and densely packed suburban neighborhoods, the risk of body damage is even higher.

That’s why having a trusted regional collision repair partner who understands refuse vehicles and can turn repairs quickly is essential to keeping your operation efficient and compliant.

The Unique Challenges of Refuse Vehicle Collisions

Why Garbage Trucks are Collision Prone

Refuse vehicles operate in some of the toughest conditions in the commercial fleet world. A typical collection truck may make 500-1,000 stops per day, reverse into driveways or alleys, and maneuver through tight streets, often before sunrise. Add reduced visibility, driver fatigue, and frequent backing, and accidents become almost inevitable.

Common risk factors include:

- Frequent stopping and reversing in residential zones

- Limited rear visibility due to large bodies and mirrors

- Operation in confined urban and suburban routes

- Repetitive motion and driver fatigue over long shifts

Common Types of Body Damage

It doesn’t take much to take a garbage truck out of commission. Refuse fleets regularly face:

- Side panel dents from backing into posts or trees

- Front-end damage from abrupt stops or low-speed collisions

- Read-end impacts from following vehicles

- Hydraulic housing damage during lift operations

- Mirror and lighting breaks from tight clearances

- Paint and cosmetic wear from daily debris and branch scrapes

Unlike standard commercial trucks, refuse vehicles present unique repair challenges due to their specialized hydraulic systems, heavy-duty frames, and integration of collection mechanisms with the vehicle body.

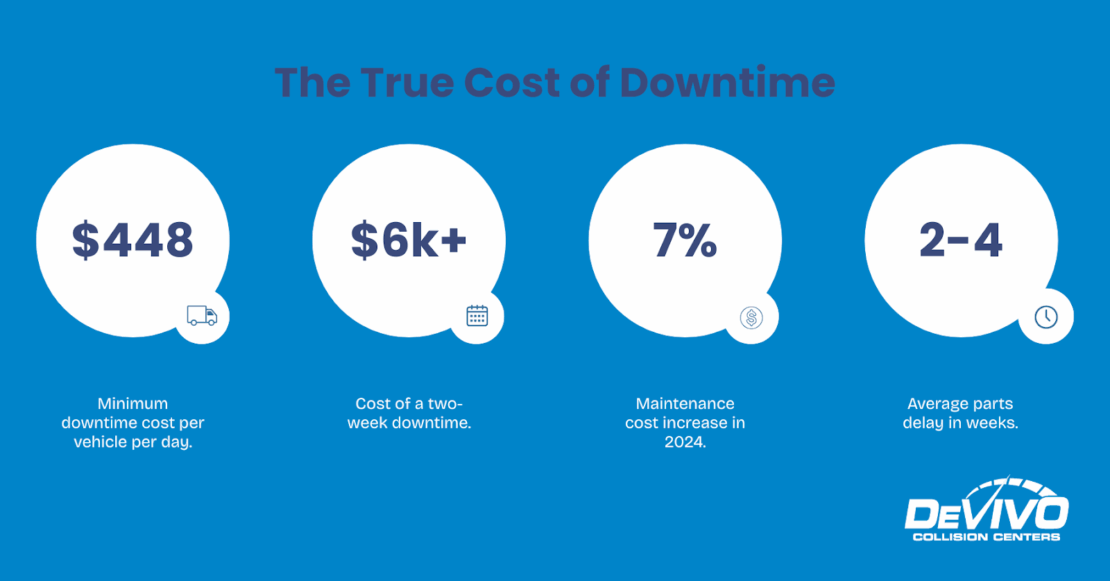

The True Cost of Delayed Repairs

When one of your trucks is down, the expenses add up fast, often beyond the initial body repair estimate.

Direct Costs

- Maintenance costs rose 7% in early 2024.

- Tire prices increased 8.5% year-over-year, while parts delays continue to slow repair times.

- Route disruption often requires driver overtime or additional trucks to fill in.

Indirect Costs

- Municipal contract penalties for missed pickups.

- Customer service complaints and loss of goodwill

- Driver morale issues from overextended workloads

- Safety risks if damaged trucks remain in service

- Reduced resale value during fleet rotation

At an average downtime cost of $448 – $760 per day, a two-week delay could set a fleet back $6,272 – $10,640 per vehicle. For multi-truck operations, those losses compound quickly.

Regional Operating Challenges in Connecticut and Massachusetts

Weather & Environmental Factors

New England weather isn’t kind to metal.

- Winter salt accelerates corrosion on exposed panels.

- Freeze-thaw cycles worsen existing dents and cracks.

- Rain and road grime degrade paint and seals over time.

High-quality paint, proper undercoating, and corrosion-resistant materials are critical for any long-term body repair.

Local Operating Conditions

Refuse fleets in Connecticut and Massachusetts face additional regional challenges:

- Historic neighborhoods with narrow, winding roads

- Dense suburban communities (Hartford County, Greater Boston) with limited maneuvering room

- Frequent interaction with school buses and morning traffic

- Seasonal leaf and yard waste pickups adding route strain

- Urban congestion around Boston, Hartford, and New Haven

What Fleet Managers Should Look for in a Body Shop

Not every collision center is equipped to handle a refuse vehicle. When choosing a repair partner, look for these key qualities:

Specialized Expertise

- Experience repairing rear-, front-, and side-loader refuse trucks

- Knowledge of hydraulic systems and frame structures

- Familiarity with Mack, Peterbilt, Freightliner, and Autocar chassis

Efficiency & Turnaround Time

- In-house frame straightening and paint capabilities

- Strong parts sourcing relationships to avoid long delays

- Insurance coordination support

Quality That Lasts

- Use of OEM-certified parts where possible

- Paint-matching and rust prevention procedures

- Documentation for fleet compliance and resale records

Geographic Convenience

Two locations reduce downtime and transport costs:

- Middletown, CT: Serving Hartford, New Haven, and all of Connecticut and Rhode Island

- Randolph, MA: Serving Greater Boston, the South Shore and all of Massachusetts and Rhode Island

Both our Middletown, CT, and Randolph, MA locations offer pickup and delivery services for fleet vehicles, reducing transport time and keeping your trucks on route.

Preventive Strategies to Reduce Future Damage

Even the best repairs can’t eliminate every risk, but proactive management can reduce frequency and severity.

Driver Training

- Backing procedures and spotter communication

- Mirror and blind spot awareness

- Smarter route planning to avoid tight turns

- Refresher courses in defensive driving

Technology Solutions

- Backup and side-view cameras

- Sensor-based proximity alerts

- Route optimization software

- Telematics for tracking driver behavior and braking patterns

Fleet Maintenance Integration

- Include body inspections in preventive maintenance (PM) cycles

- Address minor scratches or dents early to prevent corrosion

- Apply protective coatings during offseason

- Regularly check mirrors, lights and hydraulics

Why Choose a Regional Specialist with Multiple Locations

DeVivo Collision Centers understands the demands of municipal and private waste haulers across New England. With two purpose-built heavy vehicle facilities, our team provides expert collision repair designed to keep fleets moving.

Benefits of Regional Expertise

- Deep understanding of Connecticut and Massachusetts operating environments

- Faster turnaround thanks to local supplier networks

- No long-distance transport or parts shipping delays

Our Facilities

- Middletown, CT: Centrally located for Stamford, Hartford, and Danbury fleets

- Randolph, MA: Convenient to Greater Boston, Brockton, and Westborough

What Sets Us Apart

- Commercial-grade paint booths for full-size refuse trucks

- Heavy-duty frame straightening equipment

- Technicians trained in refuse vehicle repair

- Insurance relationships for smoother claim handling

Get Your Fleet Back on Route Faster

When one of your trucks goes down, you don’t have time to wait. Contact DeVivo Collision Centers today.