Offering Commercial Vehicle Alignment in Connecticut

For fleet operators and commercial vehicle owners, from delivery vans to box trucks, buses, and work trucks, wheel alignment is essential for safety, compliance, cost savings, and long-term fleet reliability. At DeVivo Collision Centers in Middletown, CT, we offer professional commercial vehicle alignment to keep your fleet running straight and smooth.

Why Alignment Matters for Commercial Vehicles

Proper wheel alignment ensures that all four wheels point in the precise directions specified by the manufacturer. Misalignment can have costly effects on commercial vehicles:

1. Extended Tire Life

Misaligned wheels cause uneven tire wear and can reduce tire life by up to 20-25%.

2. Better Fuel Efficiency

Misalignment increases rolling resistance, reducing fuel efficiency by 1-3% or more across a fleet.

3. Enhanced Safety & Handling

Misaligned vehicles can pull to one side, vibrate, or handle unpredictably. These are serious safety risks for heavy or loaded commercial vehicles. And can lead to serious accidents that could have you coming right back to us.

Signs Your Vehicle Needs Alignment

Fleet drivers and maintenance teams should look for:

- Uneven tire wear

- Vehicle pulling to one side

- Steering wheel off-center

- Vibrations at highway speeds

- Decreased fuel efficiency

How Collision Damage Affects Alignment

Even minor accidents, pothole hits, or curb impacts can knock wheels out of alignment, sometimes without visible damage. Alignment is critical for:

- Restoring safe handling

- Preventing uneven tire wear

- Ensuring vehicles meet inspection standards

Post-Repair Alignment Requirements

After collision repair, especially if suspension, steering, or frame work was done, a commercial alignment should be performed before returning the vehicle to service.

Connecticut & Massachusetts Inspection Standards

- Connecticut: Commercial vehicles subject to DOT standards must pass periodic inspections. Misalignment affecting steering, tires, or suspension can lead to inspection failures.

- Massachusetts: While Randolph, MA doesn’t currently have commercial alignment services, vehicles operating there must meet similar inspection standards. Fleet owners can send those vehicles to Middletown, CT for alignment.

Alignment vs Frame Straightening

- Alignment: Corrects wheel angles relative to each other and the road.

- Frame Straightening: Restores the vehicle’s structural geometry after an impact.

Both may be required after collisions. Misalignment without proper frame repair can cause recurring problems.

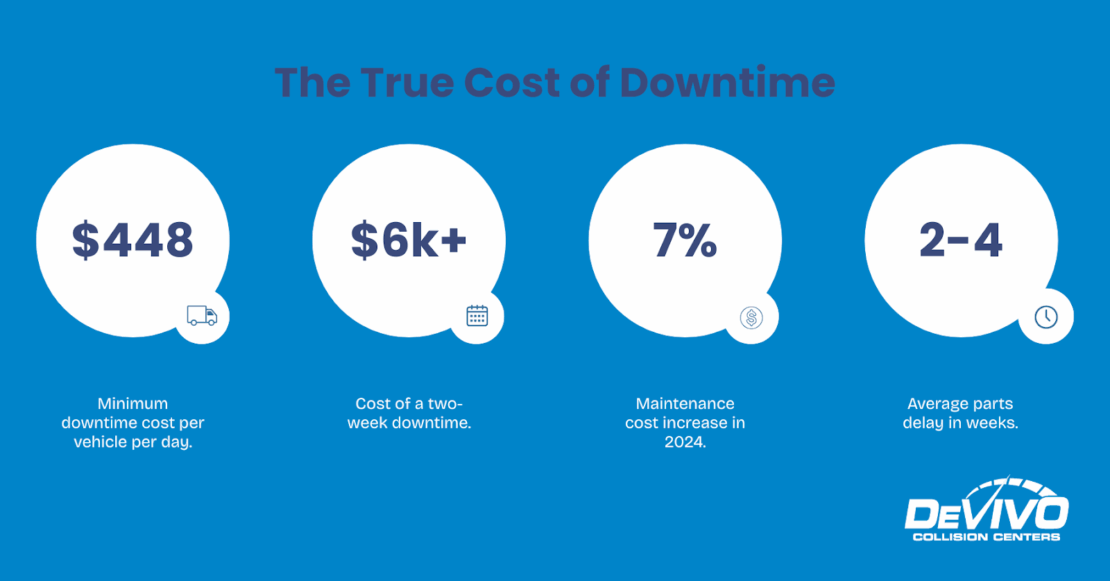

Impact on Fleet Costs

Neglecting alignment can increase fleet operating costs due to:

- Premature tire replacement

- Higher fuel consumption

- Extra suspension maintenance

Even minor misalignment can reduce tire life by 50% and fuel economy by 5-10%, which adds up fast for commercial fleets.

Specialized Equipment & Expertise

Commercial vehicles vary widely. Buses, delivery vans, box trucks, and utility vehicles all require heavy-duty alignment racks, computer systems, and trained technicians. Not every shop can align commercial vehicles properly.

DeVivo Collision Centers in Middletown, CT is equipped with specialized commercial alignment equipment from Hunter to handle your fleet safely and accurately.

Why Not All Shops Can Align Commercial Vehicles

Passenger vehicle alignment equipment is not designed for heavy-duty frames or multi-axle setups. Many collision shops cannot perform commercial alignments, but DeVivo invests in the right tools and technician training to get it done correctly.

Commercial vehicle alignment is essential for safety, compliance, and cost efficiency. Collision alignment protects tire life, fuel efficiency, handling, and inspection readiness.

At DeVivo Collision Centers in Middletown, CT, our commercial alignment services ensure your buses, box trucks, delivery vans, and utility vehicles are properly aligned, safe, and efficient, keeping your fleet on the road and your costs under control.